Hse Manual Handling Risk Assessment Filter

Legal duties Employers have a legal obligation to protect the health and safety of their employees and other people who might be affected by what they do. Some health and safety regulations are particularly relevant to dealing with back pain in the workplace. Regulation 3 requires that all employers assess the risks to the health and safety of their employees while they are at work. Require an employer to carry out a risk assessment on the manual handling tasks that pose a risk of injury.

As amended (DSE Regulations) - some users of visual display units may get aches and pains, including back pain. Fast Furious 7 Mkv Download For Pc. The regulations set out what employers need to do if their employees are habitual users of DSE. Specific advice on DSE and the DSE regulations. - regular long-term exposure to whole body vibration (WBV) is associated with back pain. The regulations require an employer to take actions to protect persons against risk to their health and safety arising from exposure to vibration at work. More information can be found at the HSE’s vibration website.

Back pain in the workplace Causes of pain Back pain can be caused by different work factors. The exact cause is often unclear, but back pain is more common in occupational roles that involve: • repetitive tasks - such as manual packing of goods • force - heavy manual labour, handling tasks, pushing and pulling loads that require excessive force • posture - poor/ awkward postures such as stooping, bending over or crouching • duration - maintaining the same position for long periods of time e.g. Working with computers or driving long distances. Also working when physically overtired • vibration - operating vibration tools • cold temperature - working in low temperature environments e.g. Outdoor working in winter Things to remember about risk factors for back pain Risk factors may be experienced during non-occupational activities. In addressing any issue of back pain it would be a mistake to focus solely on the workplace.

As individuals we are all different, the variation exists for example in our size, shape, strength, endurance, flexibility, knowledge, experience and skill. Two individuals exposed to the same combination of risk factors and to the same degree will respond differently. One employee may NOT experience any discomfort, while another might develop back pain. Other predisposing factors can also increase the risk of developing back pain. Consult your employees You have a legal duty to consult with all your employees or their elected representatives. Talking to your staff is good because they know what they find difficult and often have good ideas about how to improve things.

Involving employees and safety representatives in discussions about how to improve health and safety will also make it easier to agree changes and employees will be more likely to follow procedures that they have helped to design. Some people are more susceptible to back pain than others, so it is important to consult employees in the risk assessment process. Predisposing factors Many factors increase the risk of developing back pain. Some of these factors are important risk factors for the development of persistent back pain. • previous back injury - the single best predictor of back pain is a previous injury. Relapses are common after a significant episode of back pain • alcohol and drug abuse - alcohol and illicit drug use have been shown to increase one’s risk for back pain • smoking - studies have shown that smokers are at greater risk of developing back pain than non-smokers. It is thought to be due to reduced oxygen supply to the spinal discs and decreased blood oxygen from the effects of nicotine on constriction of the arteries • level of activity (physical fitness) - the strength and endurance of the back and abdominal muscles have been shown to be related to the development of back pain.

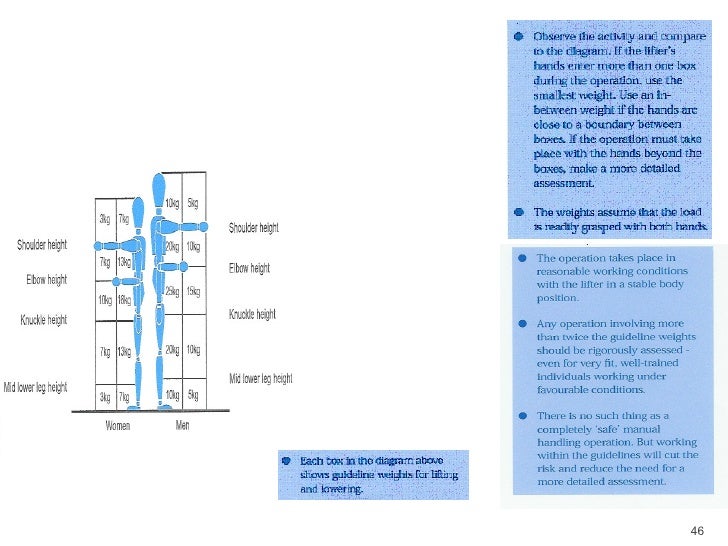

Manual Handling Risk Assessment Filter Identify all manual handling tasks. According to the Health and Safety Executive (HSE), manual handling. Manual handling risk assessment detailed assessment guidelines filter. 1 The Manual Handling Regulations set. Lifting a tea cup, will involve negligible handling risk. To help identify situations where a more detailed risk assessment is necessary, HSE has developed a filter to screen out straightforward cases.

Studies have shown that physical fitness and conditioning may prevent back injuries • obesity - studies have shown an increase in back pain in obese individuals • sports and hobbies- such as skiing, gymnastics and contact sports such as football and rugby increase the risk of developing back pain as a result of injury • psychological and social factors- it is increasingly recognised that a wide variety of psychological and social factors can increase the risk of back pain.

Involving staff, students, tenants, contractors or visitors on University premises or during field trips must be reported. Manual handling at work, such as lifting, putting down, pushing, pulling or carrying, is a major cause of injury and ill health. In the University, manual handling injuries account for the majority of RIDDOR reportable injuries. Manual Handling Standard The University's Manual Handling Standard forms part of the for controlling risks from manual handling and complies with the (.pdf).

The Regulations require the University to take action if hazardous manual handling is carried out and to reduce the risk of injury by: • avoiding hazardous manual handling so far as is reasonably practicable • making a suitable and sufficient assessment of any hazardous manual handling that cannot be avoided • reducing the risk of injury so far as is reasonably practicable Staff are required to use equipment provided and follow any safe system of work to reduce the risk from manual handling. Other health and safety standards may apply to the controls you put in place to manage the risk: • • • • • • •. In accordance with the all staff and students are required to comply with the Manual Handling Standard.

Heads of departments/sections You will need to have effective systems in place for ensuring the risks from manual handling by staff are controlled. Line managers and supervisors You will need to ensure the manual handling risk assessments and risk control measures are implemented in your area of responsibility and ensure that staff follow them. Staff responsible for education or research You will need to ensure manual handling risks are assessed and departmental procedures implemented. • Risk assessment. • (.pdf) First, think about the routine and the non-routine manual handling operations that may be carried out in your area. Speak to people and gather information on the range of activities carried out to get an understanding of the possible problems. You should have in your general risk assessments already identified the manual handling that may cause injury.

The next step is deciding whether the manual handling activity can be eliminated or avoided. If it can be eliminated or avoided record that on your risk assessment. If it cannot be avoided or eliminated, consider whether it can be automated or mechanised, bearing in mind that this may introduce other risks.

If it cannot be eliminated, avoided, automated or mechanised you will need risk assess the activity and decide how detailed your manual handling risk assessments should be. You can use our (.pdf) to help you identify whether the manual handling activity is low or high risk.

If it is within the filter values the activity is probably low risk and the findings can be recorded in your general risk assessment. If it is outside the filter values the activity will need a manual handling risk assessment because it is likely to be high risk. Carrying out a detailed risk assessment You will need to examine the manual handling activity risks. They are grouped into task, individual, load, environment and other factors (TIELO).

• Task - this covers how the activity is organised and covers duration, frequency performed, ability to take breaks, the position of the load in space in relation to the person moving it, as well as the position of the person in the workplace carrying it out. • Individual capabilities - this covers the ability of the person carrying out the task and personal attributes that may increase the risk of harm. It includes consideration of existing health problems, pregnancy, young workers, level of training and specialist needs.

• Load - this covers what is moved and the characteristics of the load. Size and weight as well as stability and other hazardous properties. • Environment - this covers where the task is carried out and the factors that may increase risk, such as postural constraints, lighting, floor condition, ramps and stairs. • Other factors - for example, including the impact of personal protective equipment and clothing. There are two levels of manual handling assessment: • The for assessing the most common manual handling risk factors. They help prioritise action to control the risk. They have assessment score sheets to record you assessment findings.

• The full assessments are (.dotx) and the (.dotx). They help you work through the TIELO risk factors in a systematic way and add information that’s not covered by the MAC, V-MAC, RAPP and ART tools. The tool findings can be used here. You may find that for complex tasks more than one detailed manual handling risk assessment is required to take into account the lifting, carrying, pushing and pulling aspects of the activity. Advice and support on manual handling assessment is available from the Health and Safety Advisory Service.

• Who carries the out the risk assessment. Everyone will be able to use the (.pdf) to identify low risk or high risk manual handling activities. It is recommended that people who record the low risk manual handling findings on the general risk assessments will have completed. However, if you have high risk manual handling activities the assessor will need to be competent in using the HSE toolkits and the full assessments. It is recommended that for departments and sections where manual handling forms a significant part of the workload, key departmental staff are trained to assess the high risk activities. To find out about the benefits of doing this and how to go about training departmental manual handing risk assessors • Reducing the risk. • (.pdf) The most effective way to prevent manual handling injuries is to avoid the activity, automate or mechanise the process.

Where this is not possible control measures should be put in place to reduce the TILEO hazards so far as is reasonably practicable. Handling aids such as trolleys can reduce the risk. Trolleys should be regularly inspected and maintained to ensure they are safe to use. Some lifting equipment may need to undergo. In offices an annual inspection is usually sufficient.

More frequent inspections may be needed if the equipment is used frequently or in environments where they could become damaged more easily. In addition, users should carry out checks before they use it to ensure the equipment is safe. Equipment should be marked or tagged with the last date of inspection, who carried it out and the equipment reference as a minimum and tags can be used to record this. A simple sticker containing the information can be used.

Equipment that fails the inspection or user check must be marked to indicate that they are not safe to use and taken out of use. • Good practice Offices • Offices and low-risk environments: (.pdf). • (.pdf) Cleaning • Catering, hospitality and retail • (.pdf) (HSG196, 2nd Ed.

Laboratories •. Libraries • (.pdf) has manual handling solutions for book issue and return, re-shelving books, moving shelving and other equipment and using trolleys. Workshops and manufacturing • • • • • • Information, instruction and training.

You should ensure people at risk from manual handling receive the appropriate information, instruction and training when they start work or as soon as possible after the need has been identified. The aim of refresher training is to update and reinforce manual handling training and safe behaviours. Possible triggers for refresher training are new manual handling activities, significant changes to the risk assessments or new risk assessments, a manual handling accident or when monitoring has shown that people's skills need updating. Contact HSAS if you would like more advice on training frequency, how to carry out effective training and support in carrying out full manual handling risk assessments. Low-risk activities For low-risk manual handling activities, the people at risk should read the (.pdf) leaflet and be aware of the findings from the general risk assessment.

This should be carried out as part of their. High-risk activities In addition to the low-risk training, the people at high risk from manual handling will require 'hands on' or kinetic manual handling training. The kinetic manual handling training is delivered face to face and includes the theory behind safer handling techniques and the health effects of poor handling techniques. The course should contain a practical session where the findings of the detailed risk assessment are communicated to the people at risk. In the practical session trainees should perform the task and handle the loads they work with. It is important to carry out the training in the environment in which they work.

If required, individuals with specific requirements may need additional training to ensure their safety. HSAS courses HSAS can help you develop and deliver kinetic. There are a variety of training aids available to you.

HSAS has a trained manual handing trainer who can assist managers in developing and delivering manual handling training based on their detailed risk assessments. However, it is strongly recommend that in departments and sections where manual handling forms a significant part of the workload, key departmental staff are trained to deliver manual handling and to carry out detailed risk assessments.

Buku Keperawatan Jiwa Pdf Creator on this page. To find out the advantages and benefits of doing this and how to go about training departmental trainers. Further information and resources • (.pdf) • • (.pdf) •.